OUR INDUSTRY

Steel has played an important role in New Zealand for over 200 years and will continue to do so far into the future.

After the 1931 Napier earthquake, a ship loaded with steel for the Sydney harbour bridge construction, was diverted to Napier to redirect its steel shipment to the rebuild of wool sheds to support the local post earthquake economy.

Those wool sheds were eventually deconstructed and eighty three years after that first deployment, those same steel beams were incorporated into the construction of new buildings in Napier.

If the embodied carbon in that steel had been fully factored into the original use buildings – as per today’s environmental impact measuring practices – then that same steel contributed less CO2 to the construction project than the contractors did in flipping the tops off the beer bottles for the roof shout!

This is what it looks like when you consider the life of a product in environmental assessments rather than just considering the life of the first, and often the only, building the product is embedded in.

There are many stories like this one and I wonder what buildings the woolshed steel will be redeployed into as another 80 years roll by.

Steelmaking in New Zealand

New Zealand’s steel industry dates back to the 1800s, when European settlers first recognised the potential of the magnetic black iron sands found along the west coast of the North Island.

Over the next century, attempts to smelt iron from these sands faced challenges—traditional blast furnaces would clog due to the sand’s unique composition. By the early 20th century, attention shifted to limonite, a rich iron ore found in the Golden Bay area. This material could be smelted more easily, and in 1920, the Onekakā Iron and Steel Company was established. From 1924 to 1935, it led New Zealand’s iron smelting efforts, but economic and market conditions eventually made the operation unsustainable.

Despite setbacks, the potential of iron sand remained compelling. It wasn’t until the 1960s, with the development of direct reduction techniques and Electric Arc Furnaces (EAFs), that engineers successfully pioneered a process to unlock the value of New Zealand’s iron sand deposits—laying the foundation for a modern, sustainable steel industry.

New Zealand Steel is the only manufacturer of Steel in New Zealand which operates at Glenbrook in Auckland. The Glenbrook plant is the only steel making plant in the world that produces steel from iron sand. NZ Steel will shortly be commissioning its new state of the art EAF which will draw raw product from the metal recycling operators and reduce CO2 emissions from the Glenbrook site by up to 1,000,000 tons per year.

The Rise of Electric Arc Furnaces

While traditional blast furnaces rely on carbon from coal to produce virgin steel. In contrast, EAFs use electrical induction to melt recycled steel, eliminating the need for additional carbon. The primary source of emissions in EAFs comes from the electricity used—meaning that when powered by renewable energy, such as the NZ Steel EAF at Glenbrook Auckland, emissions drop even further.

Today, about 30% of global steel production comes from EAFs, and research continues into technologies that could produce zero-carbon steel.

Why Steel Endures

Throughout history, steel has remained vital to human progress thanks to its:

From ancient tools to modern skyscrapers, steel continues to shape our world—and its future looks even more sustainable.

Steel and the Circular Economy

Steel is the only building material that can be recycled infinitely without losing quality. That’s why it’s often called the “rockstar” of the circular economy. In contrast, many materials labelled as recyclable are actually “downcyclable”— each time those products are ‘recycled’ the quality and useability is downgraded and eventually they end up in landfills.

Recycling steel offers a wide range of environmental, economic, and practical advantages that make it a cornerstone of sustainable development:

Recycling steel uses significantly less energy than producing steel from raw iron ore. In fact, it can save up to 75% of the energy required for traditional steelmaking. This efficiency helps reduce greenhouse gas emissions and conserves valuable resources.

Electric Arc Furnaces (EAFs), which are now commonly used in steel recycling, emit far less CO₂ than blast furnaces. When powered by renewable energy, EAFs can reduce carbon emissions to near zero—making recycled steel a key player in climate-conscious manufacturing.

Recycling steel reduces the need for mining iron ore and coal, preserving natural landscapes and ecosystems. It also minimizes the environmental impact of extraction and transportation.

Unlike many materials that degrade with each recycling cycle, steel can be recycled indefinitely without losing its strength or quality. This makes it ideal for a truly circular economy.

Steel recycling supports a robust industry that creates jobs in collection, processing, and manufacturing. It also lowers production costs for manufacturers by reducing the need for raw materials and energy.

Recycling steel helps divert millions of tons of waste from landfills each year. This not only reduces environmental pollution but also extends the lifespan of landfill sites. Approximately 90% of steel from building demolition is reused or recycled.

Today iron for steel production is smelted by New Zealand Steel at Glenbrook, south of Auckland, using iron sand from North Waikato Head.

The majority of CO2 emissions (about 80 per cent) come from the chemical process of making iron. New Zealand Steel has significantly reduced the intensity of its emission profile since the 1990s and is continuously looking at cost effective ways of reducing its energy usage and CO2 emissions. Find out more about the company’s sustainability practices here.

Pacific Steel is New Zealand’s only manufacturer of wire rod, reinforcing bar and coil product, using virgin iron-sand feed from New Zealand Steel.

Each year Glenbrook produces 650,000 tonnes of steel for products such as roofing, shelving, machines and tools, contributing about .25% of the nation’s GDP. It is the only mill in the world to make steel from iron sands. It also generates around 60% of its electricity on site from co-generation.

New Zealand has more than 85 steel and stainless steel fabricator businesses which cut, bend and assemble steel into a wide range of products such as pre-fabricated structural steel, machinery, piping and more.

Industry capacity – 80,000 tonnes of structural steel annually

Structural steel framing has over 50% market share of the national multilevel construction market – 80% in Christchurch.

Moving to a low-emissions economy is the right thing to do now and for future generations.

New Zealand’s steel industry has a role to play because steel is fundamental to a new style of economy that underpins a more sustainable and low-emissions future – the circular economy.

In a circular economy society reduces the burden on nature by ensuring resources remain in use for as long as possible through use, reuse, remanufacture and recycling.

Steel is fundamental to the circular economy, a permanent material that can be reused and recycled infinitely. Read more about steel’s contribution to a circular economy low carbon future.

The Ministry for the Environment’s waste programme aims to transition New Zealand to a circular economy and is working with the global Ellen MacArthur Foundation to accelerate that.

We have the opportunity to work together and with government to accelerate the circular economy.

The SSC’s work focus is to help establish systems and tools that will enable businesses to action the circular economy through improving sustainability through the entire supply chain from steelmaking, manufacture and construction to reuse, remanufacture and recycling.

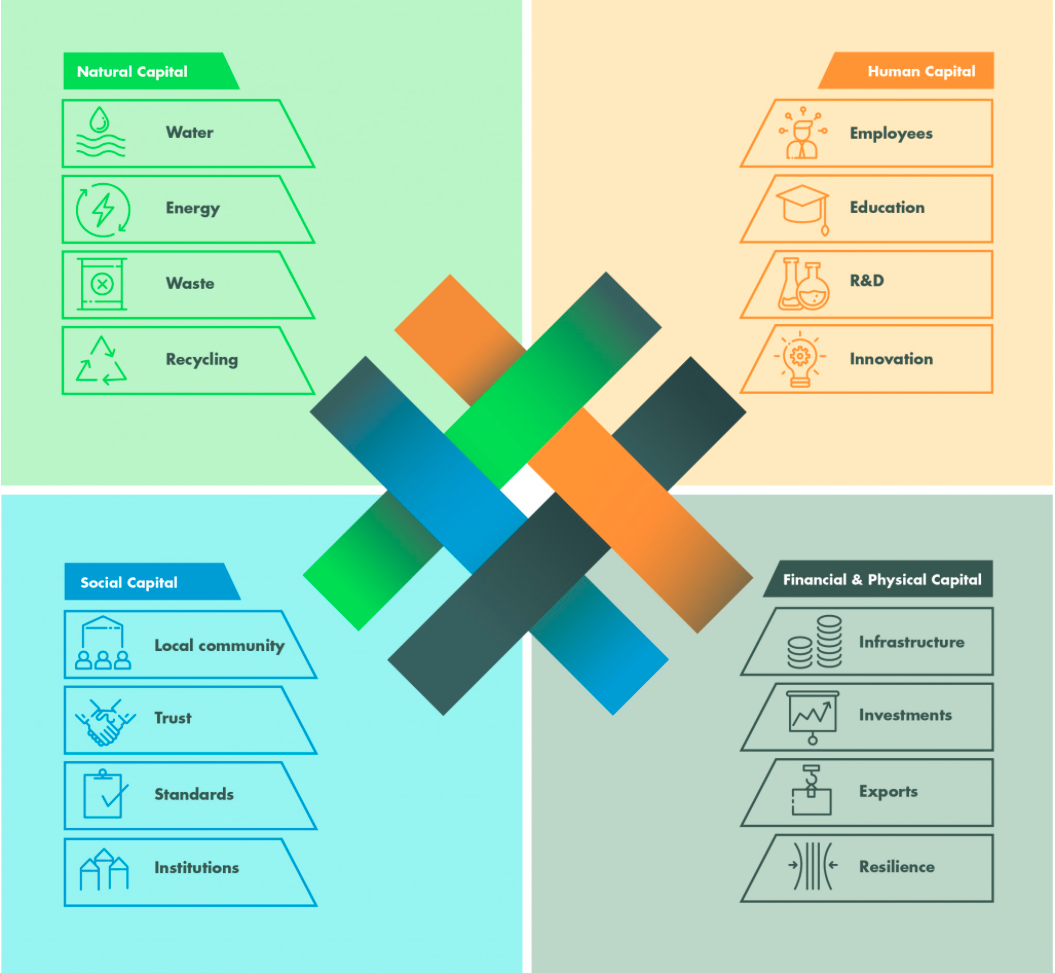

Our mission is to enhance the industry’s contribution to New Zealanders’ standard of living under Treasury’s Living Standards Framework.

This requires the industry to deliver across the four capitals: human, social, financial/Infrastructure and natural.

The steel industry has long been a part of our society and it supports people and communities across Aotearoa New Zealand. “It is part of our local metals manufacturing sector, which generates over $3.2 billion in gross domestic product each year1, and that provides over 28,000 full-time equivalent jobs in the steel industry2

The steel industry is also an important source of employment and career opportunities for Māori and Pacific peoples across New Zealand.3

1. Manufacturing Matters – February 2020

2. BERL (2020) New Zealand Steel Industry: Employment Created Outside the Industry (available from SCNZ).

3.Māori and Pacific in steel industries_final report 21December2021