Kernohan Engineering Goes Carbon Neutral

- Categories:

- Case studies

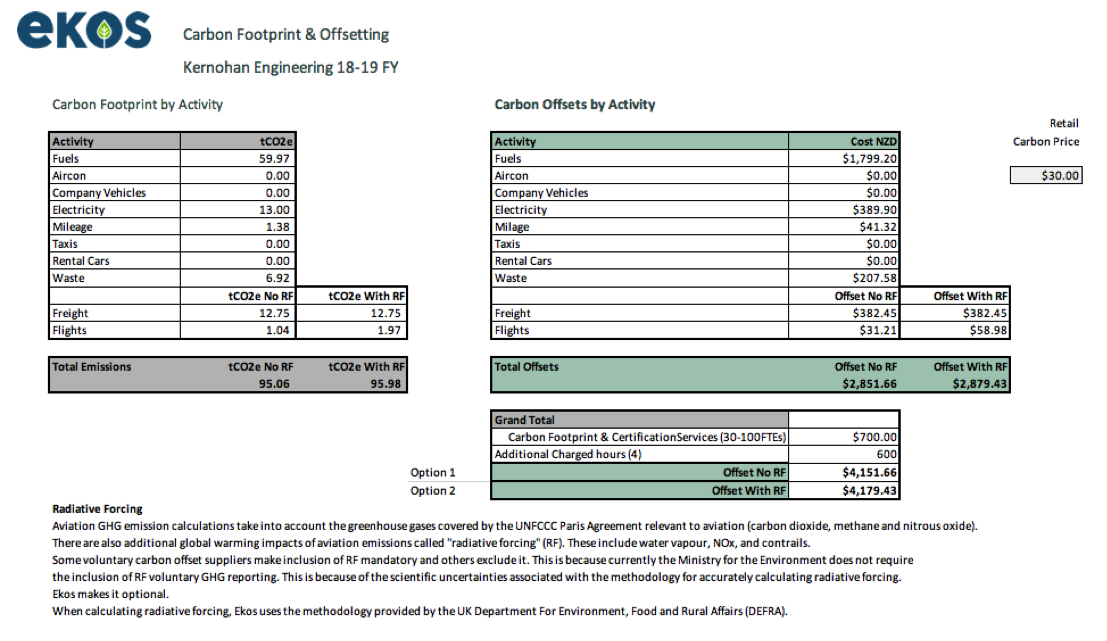

Taking the journey to carbon neutrality isn’t as hard as you might think. Nelson-based Kernohan Engineering, a maintenance service company supporting the timber, oil and gas, fishing, dairy, cement and mining industries, has recently been certified carbon neutral.

Kernohan Engineering wanted to understand its carbon footprint and to know that it was offsetting its emissions to achieve carbon neutrality. This was part of its goal to not only supporting New Zealand’s transition to a net zero carbon economy by 2050, but establish its credentials to work in the rapidly expanding, exciting and profitable low-carbon market. And, despite some challenges – it was a relatively simple process working with carbon certifiers Ekos.

What was your goal in undertaking the carbon footprint analysis and offsetting? To understand the makeup of our carbon foot print so we could better manage it, to offset it so we are a good corporate citizen, and start to move the business into the low carbon economy transformation.

What issues needed to be addressed in the process to calculate the required offsetting? Other than setting up a spreadsheet to record all our invoices that relate to emissions, the only issue was freight.

What were the challenges associated with the process? Freight was the hardest emission to calculate. The only substantive item we freight is steel. Inwards freight is made up of steel from several suppliers from various cities in NZ depending on inventory and product type. Outwards freight consists of multiple types of steel finished goods going to multiple client locations, including a trip to the galvanizing plant in some instances before it reaches its final destination.

How were the challenges addressed? It was too hard to calculate the inwards and outwards route of each individual delivery of raw or finished goods. Instead we calculated the total steel purchases and our average buy price. We then divided the buy price by the average price per tonne to get the total tonnes purchased. We didn’t allow for wastage, and just assumed that everything we purchased ended up being shipped to a client. We took our biggest orders and calculated their inwards and outwards freight journeys (as this was relatively simple), for total tonne kms. Then we took these known large orders from our total steel purchased and made an assumption on an average inwards and outbound freight journey to calculate the total tonne kms for the balance of goods. We then put a contingency factor onto the total to allow for uncertainty.

What were the criteria for success in this project? How were these met? The success criteria were to know we were offsetting our footprint, and gaining an understanding of what our footprint is comprised of. These goals were met. There is data showing that companies that have reduced their energy emissions per unit of production, increase their profitability. NZ industry typically has low energy efficiency (and low labour productivity for that matter) as well as lower margins and economic value added than many overseas markets. Now we have some baseline data to start energy efficiency work. We expect to increase energy efficiency, labour productivity and profitability as part of a wider programme. Another success criterion was to establish some credentials in the rapidly expanding low carbon sector of the economy. We see the massive economic transformation to a low carbon economy that is required, to be an opportunity to work in an expanding, exciting, profitable and rewarding market. In order to be part of this transformation we need to be credible. We believe this has been achieved as a first step.

How did ‘innovation’ and ‘experimentation’ contribute to the success of the project? It was actually a very simple process other than the freight calculation, which did require a bit of more detailed analysis.

What kind of feedback have you received on this? From customers, from stakeholders and from staff? We are only just making this known to staff, the public and customers. It’s too early to gauge feedback, other than people are generally interested and supportive.

Has the project gained or been submitted for any awards or any other accolades? Nelson City Council (where we are located), recently declared a climate emergency, and followed it up with a budget to take some sort of appropriate action. Our carbon neutral certifiers Ekos (https://ekos.org.nz/) and a member of the family that owns Kernohan Engineering are meeting with the mayor today to explain the carbon certification process. They will show Kernohan’s carbon neutral certification as an example that it is not too difficult or expensive for local business to achieve carbon neutral status. Hopefully it will inspire others to take similar action.

How has this made a difference to your business? So far it is at the upstream end of change. It is changing thinking, data collection, procurement processes and the types of suppliers and clients we seek to work with.

Approximate Time scale of project (months): Three months

Approximate Cost of project (to the nearest $50k) excluding GST: <$5K including offset costs